Description

Crafted with precision by skilled American trade workers at Griffin Armament’s headquarters in Watertown, WI, Griffin Precision Mounts™ (GPM™) are machined from lightweight, solid blanks of aircraft-grade aluminum. Engineered for precision, versatility, and durability, these mounts integrate cutting-edge features designed by snipers.

The unique, patented, split-ring design, offset on two parallel planes, provides five Accessory Interface Suite (AIS™) mounting surfaces: top, left, right, and 45° left and right offsets. This affords unparalleled ambidextrous flexibility for accessory placement, catering to both left- and right-handed users. The AIS™ utilizes a dowel pin alignment system, enabling seamless integration of modular accessories.

Designed with ergonomics in mind, GPM™ Mounts also support Rapid Transition Optic™ (RTO™) plates, which align secondary non-magnified optics with the stock’s height over comb, optical centerline. This allows for intuitive, rapid target acquisition with a simple roll of the firearm, maintaining shooter comfort and efficiency.

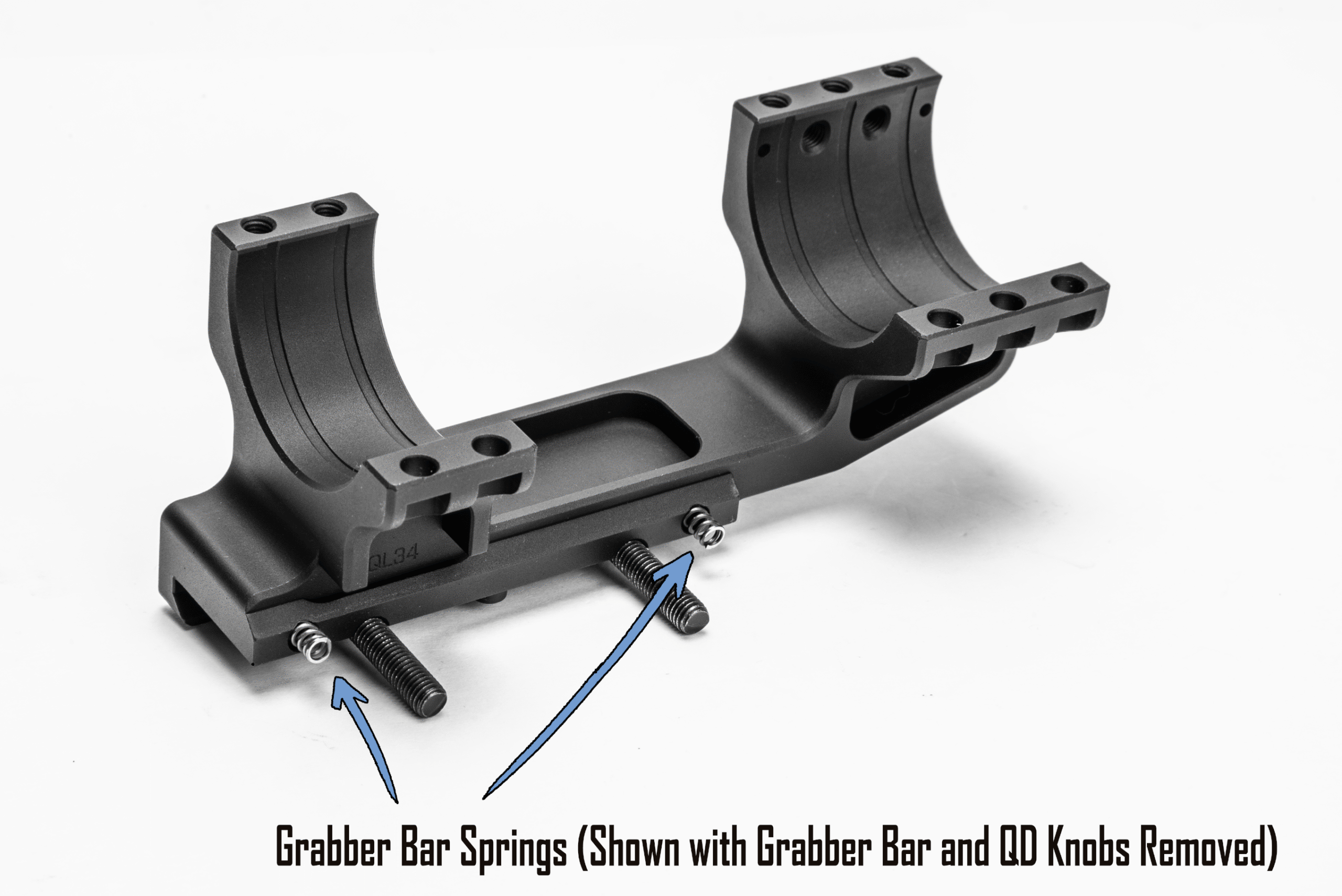

This QD version features two ball and detent style tension knobs which rigidly affix the mount to the firearm preventing inadvertent loosening under heavy fire. This QD system allows for rapid transition to another host firearm, or rapid removal of the user’s magnified optic setup in the case of a downed optic.

Supported Optics and Accessories

The AIS™/RTO™ system is compatible with a wide range of optics, including:

- Griffin Micro Sight™ (GMS™)

- Aimpoint Acro, T1/T2, H1/H2, Comp M5

- Sig Romeo

- Vortex Spark, Venom, Viper, Razor

- Trijicon RMR, SRO

- Holosun HE507C, HS407C, HS508C

- Leupold Deltapoint

- J Point, Optima, Dr Optic, Meopta, Insight Microdot

- Burris Fastfire

- CMORE STS, RTS, STS2

- Wilcox Raptar Mount

- Simrad Adaptor Plate

- Picatinny AIS™ plates

Features

- American-Made in Watertown, WI

- AIS™ Accessory Mounting Technology

- RTO™ 45 Degree Reflex Support

- Built-In 17-4 SS Recoil Lug

- Dowel Pin Accessory Alignment

- Ambidextrous Design

- QD Detented Mounting Knobs

- Unibody Construction – Reduced Zero-Retention Failure points

- Aerospace Manufacturing Methods – In-Machine Probing

- Type III Milspec Hardcoat Anodizing

- Utility-Patented Design

- Perpetual Lifetime Warranty™

What’s in the Box

- 34mm QD GPM™ Box Mount

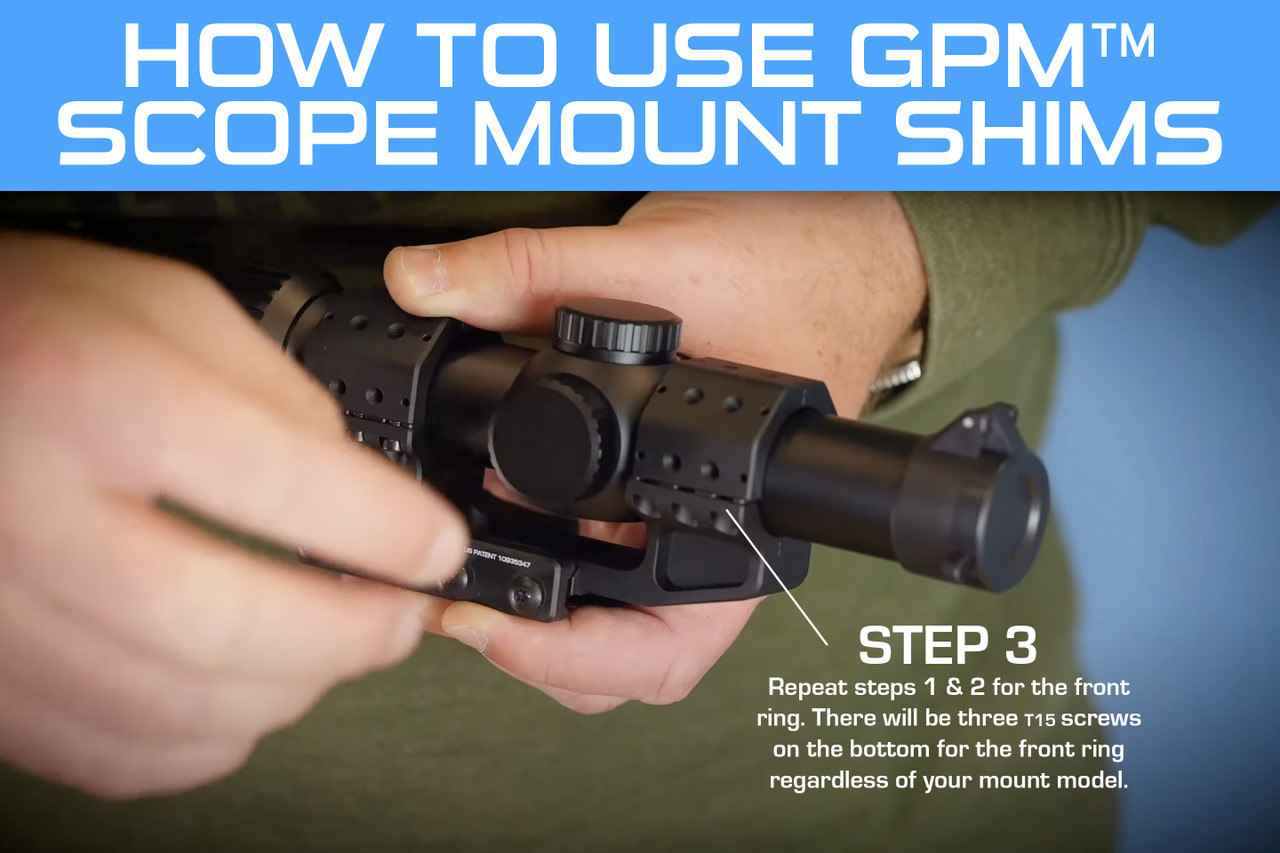

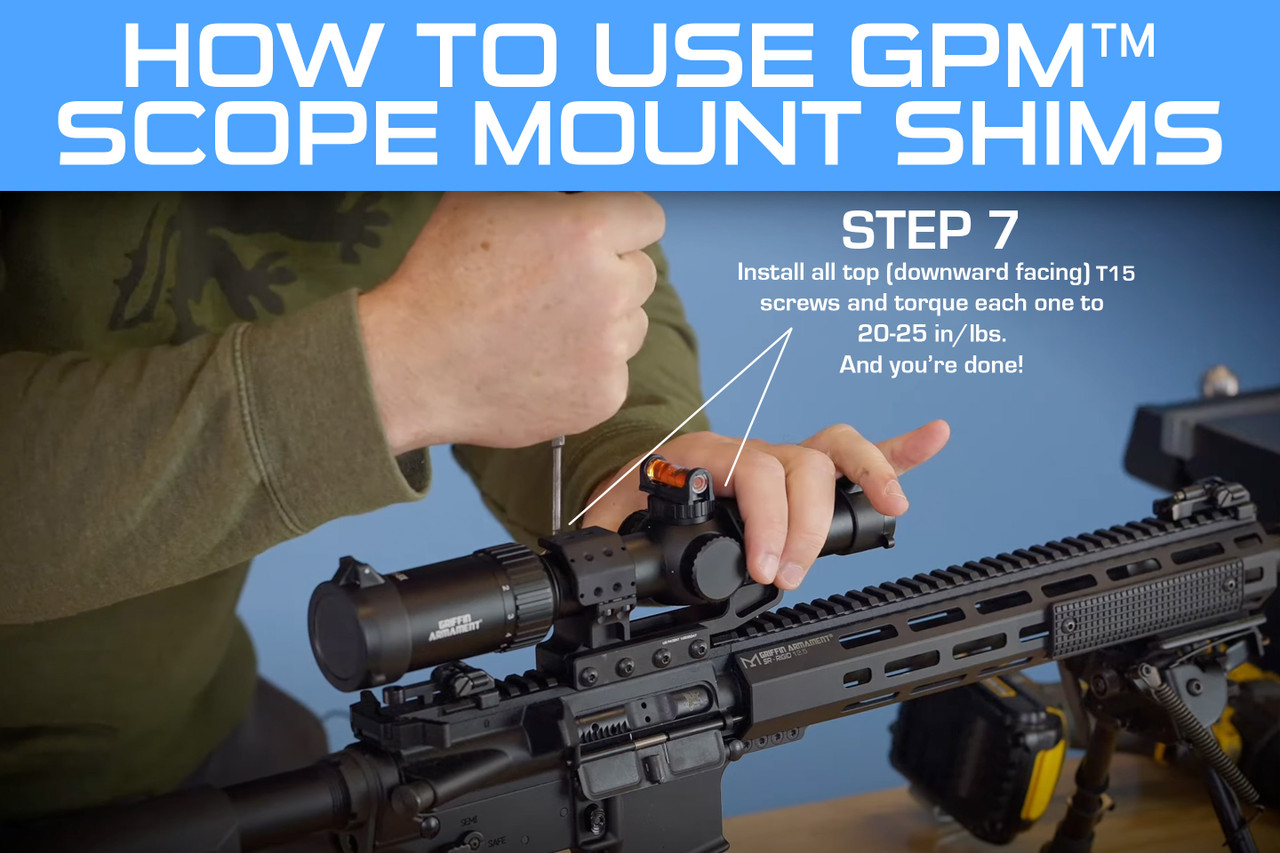

- 12 (8-40 T15) fasteners for ring clamping

- 2 (10-32 Button Head T15) fasteners for rail clamping with QD system

- T15 Allen Key

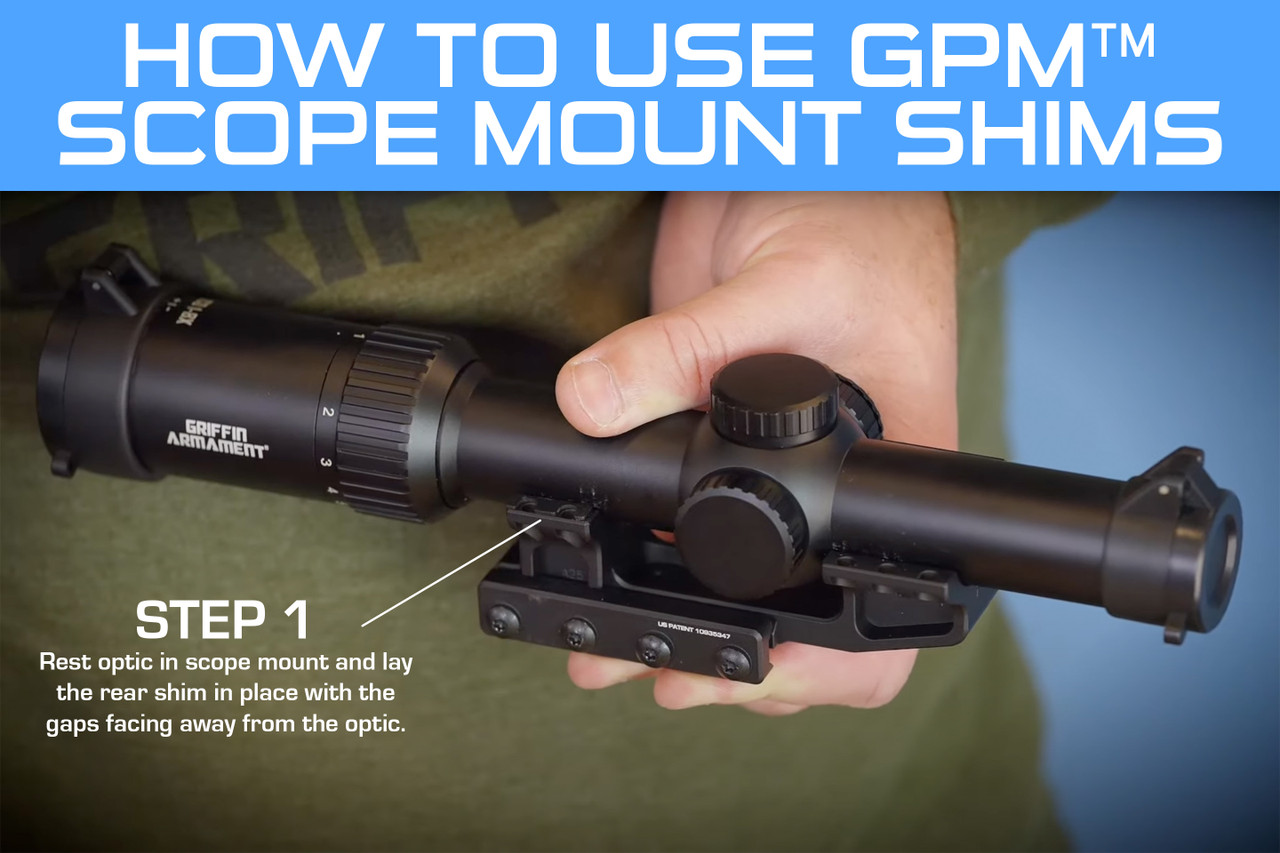

- Ring Shim Set (allows bottom ring screws to be torqued to 20 in/lbs before attaching optic mount to rail, and affords leveling afterward without a need to re-torque lower screws)

- GPM™ Manual

Installation Notes:

1.) It is a good practice to dry fit accessories to confirm screws do not protrude into the ring bores prior to mount assembly. This reduces the minimal risk of damage to optics caused by a long AIS™ accessory screw touching the optic.

2.) If QD clamp screws (long bolts on the bottom) are installed, they must be removed prior to Ring Shim installation and lower screw torqueing. Then complete re-installation of clamp screws and torque to 25in/lbs, followed by threading on the QD knobs until they engage the ball detent. This is followed by affixing the mount to the rail, tightening the QD knobs fully, and completing leveling and top screw installation and torque.

Optic Height Specifications

Optic height is measured from the top of the Picatinny rail to the centerline of the tube diameter. To calculate the height to the bottom of the ring cradle, subtract ½ the tube’s diameter from the listed height.

Reviews

There are no reviews yet.