Choosing a suppressor is a daunting task. Deciphering what you need for your application versus what you are being sold is hard to digest. Trustable data and information are also hard to find within the flashy marketing from the firearm industry. The purpose of the Choosing a Suppressor Series is to help you make the most informed purchasing decision possible. Which will result in the most satisfaction from the end user (YOU). I will be referencing Griffin Armament suppressors and accessories. However, these concepts are not exclusive to our product line and can be applied to nearly every manufacturer’s product. I hope you enjoy.

Material & Construction

When researching a new suppressor purchase, it can be hard to get a sense of how a suppressor handles and feels like in person. Looking at pictures, reading descriptions, and watching videos do not give you a sense of how the suppressor is constructed. In this article, I will go over the different types of materials used to build suppressors as well as the different methods and ways silencers are constructed. If you are trying to discern the difference between the Dual-LOK HRT and Dual-LOK 5 or the Recce 5 and Paladin 5, for example, this article will be very helpful for you.

Material

There are a handful of different materials that are used to build suppressors. Each one comes with a few pros and cons. Mostly everything in the firearms industry is a trade off after all.

Aluminum

Aluminum is the lightest and most inexpensive material to build with. Aluminum does well on the lower pressure cartridges. That’s why it is mostly found in rimfire and pistol suppressors. The main draw to choosing a suppressor that is made of aluminum is that they usually come in at a lower price point while still being lightweight. Aluminum does have a few drawbacks as a suppressor material. First is that it is sensitive to most gun cleaning practices. You will have to take care in using certain brushes and solvents to clean the suppressor. We do not recommend cleaning aluminum with an ultra-sonic cleaner. Ultrasonic cleaners can dissolve aluminum and may impact the structural integrity of the parts. The second drawback is more of a use case perspective. If you are like me and resort to brute force to fix things. Aluminum may not be the best choice as there are better options that can stand up to the abuse.

Titanium

Titanium is another lightweight material used in suppressors. Titanium is mostly found in lightweight hunting suppressors. This material can hold up to the abuse of the bigger cartridges while keeping the weight very low. Titanium can also be welded to make a tubeless silencer. We will go into what a tubeless silencer is here in a second. While Titanium is an amazing material to make a suppressor out of, it has a few drawbacks to note. The first one that comes to mind for me, mainly because I use night vision, is that titanium does not lend itself well to keeping the flash down. Titanium sends bright sparks out and seems like it amplifies the flash in low light scenarios. The next is that even though it can hold up to bigger cartridges, the host firearm barrel length and rate of fire restrictions do get limiting. I believe Titanium suppressors are best used on bolt action rifles and pistol caliber carbines.

17-4 H900 Heat Treated Stainless Steel

This is the material we use the most in building suppressors and for good reason. In our testing, this material exhibits the most wear resistance which leads to a longer service life of the suppressor. 17-4 stainless steel (SS) hits the spot between durability and weight. We are able to make the Explorr suppressors, which are a full auto rated 17-4 SS suppressor, that rival the weight of titanium suppressors.

Cleaning 17-4 SS is super easy. You can use any standard gun solvent, my go-to’s are Hoppe’s #9 and Rem oil, and a fine wire brush. If your suppressor is user serviceable, the baffles can be dropped into an ultrasonic cleaner. Just make sure to keep the finished or nitride components out. Ultrasonic cleaners can damage the finish.

The Wonder Materials

The wonder materials, as I like to call them, are the oddball materials you wouldn’t necessarily think to be used in a suppressor. These include cobalt, stellite, and Inconel. When a suppressor is made with these materials, durability is what the manufacturer is going after. The thing with these materials is that you get only marginally better durability, at best, at the cost of more weight and higher price tag.

Construction

There are a few ways suppressors are built. Each way has its own attributes on how the suppressor can be used and its performance. Let’s dive in!

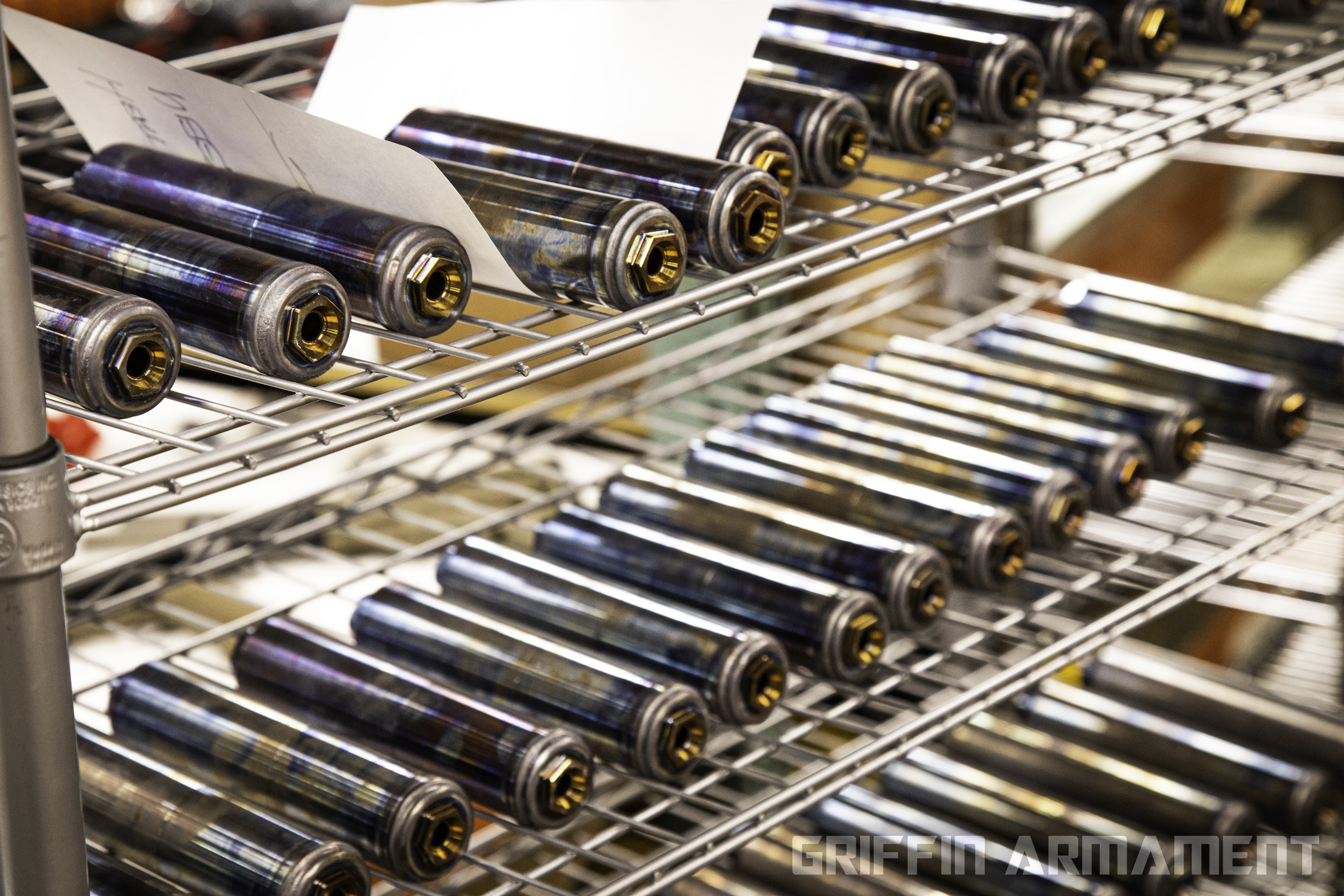

Tube-Over Fully Welded

I’ll start with what I think is the most classic and time-tested method on silencer construction. The tube-over fully welded design is what we use on the Recce, Dual-LOK HRT, M4SDK, M4SD-II, 30SDK, and the GP suppressors. Just like the name implies, it has a laser welded baffle core welded into a silencer tube body. This method of construction is insanely durable due to the silencer having the outer wall of the baffles and the tube body to contain the muzzle blast. I remember when I fixed a Recce 5 that a customer shot a full magazine of 9mm through it with a full auto MP5. All it took was a re-core and it was looking brand new. The baffles took some damage but it’s a testament to how strong this design is. A side benefit of this design is that when shooting under night vision and thermal, it takes longer for the suppressor to heat up enough to emit light in the IR spectrum.

Tube-less Fully Welded

Tube-less fully welded silencers are made by laser welding each individual baffle to each other to comprise the tube body. A telltale sign of if a suppressor is tubeless is if you can see the weld rings on the outside of the silencer.

Fun fact: Back in the old days, the weld rings were not a desirable aesthetic feature so most manufacturers grinded them down flush with the tube body.

The immediate benefit of this design is the weight savings by removing the need for an outer tube body. This can be seen in the weight difference between the Recce 5 and Explorr Taper Mount .224. The Explorr Taper Mount .224 is approximately 5.5 ounces lighter. While technically not as durable as the tube over fully welded design, the tube-less fully welded design is still very resilient. The barrel length and rate of fire ratings would come down to what material your suppressor is made from. The Explorr Taper Mount .224 has the same ratings as the Recce 5 for example.

The only drawback to this design that I can see is that, since there is less material comprising the tube body, the suppressor will emit light in the IR spectrum sooner.

User Serviceable

User serviceable suppressors can be taken apart for cleaning and easy maintenance. Examples of this are our Bushwhacker, Optimus, Resistance, Revolution, Checkmate HD, Paladin, and Sportsman Ultra-Light suppressors. With user serviceable suppressors, it allows you to shoot rimfire or a higher firing schedule of dirtier cartridge loadings without fear of your suppressor’s performance diminishing. This design offers a lot of the same benefits of the Tube-over fully welded design. However, you will have to pay more attention to what the suppressor is made from as the tube body and baffle material does vary.

The main drawback to these types of suppressors is that they tend to be heavier. This is due to the needed parts and complexity of being able to disassemble the suppressor.

Modular

Modular suppressors let the end user configure and change the length. Most suppressors in this class are user serviceable but some have removable welded baffle sections. The modular suppressor also includes the Dead Air Odessa type where all the baffles can screw together to comprise the silencer. This construction gives the most options to the end user. The suppressor can flex into a short covert package to be fit into small compartments or lengthened to maximize the sound performance. These suppressors usually fall into the category of pistol or universal suppressors due to the flexibility of this design.

The main drawback to this construction type is that as you shoot the suppressor, it will be increasingly hard to reconfigure the silencer due to the carbon buildup. I will also add that since there are more parts needed to be able to swap configurations, having an organized system to store all the parts is a must.

3D Printed

Griffin Armament does not make any 3D printed silencers, but I figured I would get you up to speed on the concept. The main draw to 3D printed silencers is the ability to use more complex baffle geometry and gas flow paths. In our testing, the juice is not worth the squeeze. In my opinion, it’s not an argument of if it is dramatically better performance, rather than a different type of performance. You must take a good look at what your application is to see if it warrants the need for a 3D printed silencer. 3D printed silencers come in at a higher price tag and are harder for the manufacturer to fix if you encounter a baffle strike. Other than that, they more or less follow the same pro’s and con’s as tubeless fully welded suppressors.

About the Author

The article was written by Jack Rapala. Jack is a USPSA carry optics shooter, night vision enthusiast, firearm salesman, suppressor connoisseur, and a customer service representative for Griffin Armament.